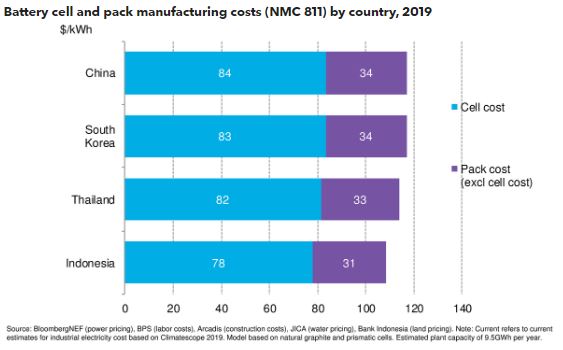

Indonesia may currently have the lowest manufacturing costs in Asia for EV and battery manufacturing. This comes after Indonesia announced in December last year that it aimed to make lithium batteries for use in electric vehicles in 2023.

BloombergNEF estimates that total EV battery pack manufacturing costs in Indonesia can be 8% lower than in China. The country also has some of the lowest labor costs and industrial power prices in Asia, supported by government subsidies. Labor and electricity account for around 6% of total EV battery pack costs, and Indonesia has plenty of nickel and cobalt reserves, along with key battery raw materials which make up 22% of total EV battery pack costs.

However, Indonesia’s grid carbon intensity is among the highest in their region at 711g of CO2 per kWh. This is as opposed to in Peru, which has the grid carbon intensity of 23p of CO2 per kWh. (Malaysia’s stats are almost as high as Indonesia’s, at 692g of CO2 per kWh.)

This may cause manufacturers who are looking for low carbon energy sources to look elsewhere. But Indonesia said it plans to develop new hydro and geothermal power plants to supply the industry with cheap, low-carbon electricity. The country plans to relocate its capital city from Jakarta to East Kalimantan, and that the city will only use autonomous and electric vehicles for mass transportation.

As for Malaysia, we reported last year that there are no new initiatives to promote usage of hybrid and fully electric vehicles in Malaysia. We still lack the incentives, infra and support structure to promote the large-scale use of what many deem the more environmentally friendly modes of transport.

[ SOURCE, IMAGE SOURCE ]