On the 9th of October, Robotics student Ken Pillonel uploaded a video that went viral on YouTube. In that video, Pillonel showed off a USB-C iPhone that he made all by himself. It almost looked too good to be true, as the USB-C cable transferred both power and data as well.

He just uploaded a 14-minute video detailing his entire process, so if you want to make your own USB-C iPhone, then you’re in luck! You just have to be really good at engineering.

How to build a USB-C iPhone

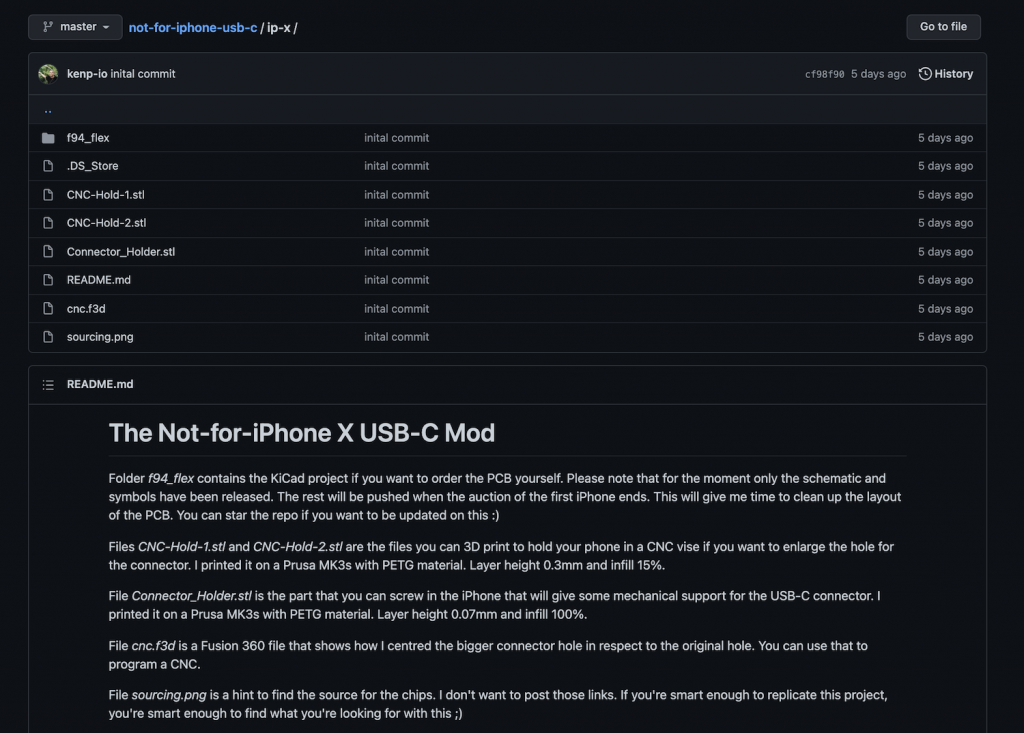

The first thing you should do is watch Pillonel’s video, where he goes over the entire process from proof of concept to final product. If you’re still interested in going through with all the steps, then proceed to his Github repository with all the files needed for the project.

After downloading the files, you need to acquire an iPhone X, the PCB, and some lightning C94 chips using the hint in the Github repository. If you want to order the PCB yourself, you can use the KiCad project in the f94_flex folder. The next step would be to 3D print the CNC phone holder and the connector holder.

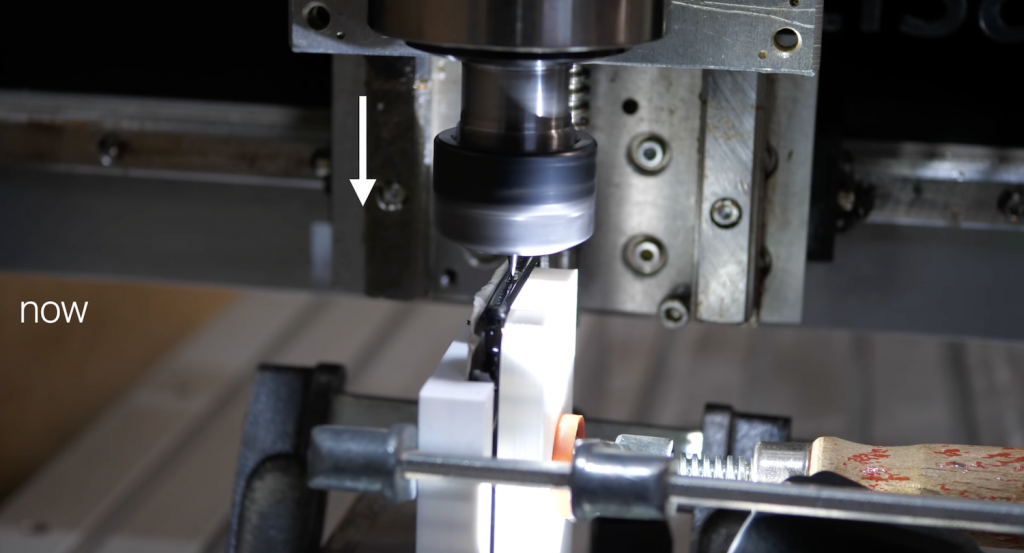

Then, you need to get your hands on a CNC machine to make the connector hole just a little bit bigger using the cnc.f3d file. Once you have all this preperation done, all that’s left to do is the assembly.

Pillonel designed the board so that it fits right in between Apple’s Taptic Engine hardware. Assembling the parts together will be tough, but it is definitely possible.

If you’ve followed all the steps properly, then you should have your own USB-C iPhone! It does seem a little daunting, so if you want to have one without building it yourself, you can join the auction for the prototype Pillonel made in the video. As of right now, the highest bid is at USD 3,800 (about RM15,783), but he notes that you should not “use it as your daily phone”.

As for future plans, Pillonel wants to make improvements like fast charging, waterproofing, and adding USB-C accessory functionality.

[ SOURCE, IMAGE SOURCE ]